In 2021, is China's polypropylene industry, is also a good annual chemical products, most of the chemicals in 2021, market prices are rising sharply, especially the main raw material of polypropylene methanol, propane, propylene, coal, naphtha, etc, it also leads to the boom of China's polypropylene industry overall in 2021. Statistics show that the average profit level of China's polypropylene industry in 2021 is 1086 yuan/ton, and the average gross profit margin is about 13%.

What is this concept?

The profit margin level of Polypropylene production in China has gradually decreased since 2017, and will reach the lowest level in the industry in the past few years in 2021. During the period of 2021, some of China's polypropylene production will suffer from periodic losses. This is also the initial performance of the imbalance between supply and demand in the industry, as well as the result of the ineffective transmission of raw material costs.

As for the production profit level of different types of polypropylene products, due to the great difference in production cost, the production economy also has great difference. According to the unit consumption of copolymer, type and cost of antioxidant, type and cost of antistatic agent, type and cost of light stabilizer, type and cost of nucleating agent, the production cost and profit margin space of different types of polypropylene can be roughly calculated.

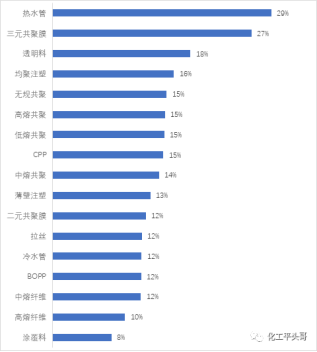

According to the calculation results, in terms of the production profit margin level of different types of polypropylene in China in 2021, the production profit margin level of hot water pipe is the highest, reaching about 29%, followed by ternary copolymer film, the production profit margin level is about 26%. At present, the production profit margin of drawing material with large polypropylene production volume will be about 11% in 2021, while the profit margin of coating material production will be the lowest at about 7.9%.

Hot water pipe is always a profitable product in polypropylene industry, but the high-end brand of hot water pipe has a higher profit level, but is limited by production technology. Coating material is a product with low profitability in polypropylene industry, because only Shanghai Petrochemical and Changling Refining and Chemical enterprises in China produce high-end coating material products, while ordinary or low-end coating materials are replaced by fiber materials. For example, homopolymer polypropylene has most brands applied in the coating material field.

In the production of high-end coating products, can be used in high-end woven bags, part of the non-woven coating and other fields. Imported coating products such as South Korea Daelim PR770B, is used as the woven bag packaging industry coating seam adhesive material.

According to the comparison of the production profit margin of different polypropylene brands, the drawing material with the largest production scale accounts for about 33% of the weight of production scale, but the production profit margin is only less than 12%. It can be seen that the homogenization caused by the scale of the market has become the main factor limiting the profit margin of different kinds of polypropylene production in China.

In addition, terpolymer film with the lowest weight of production scale only accounts for about 0.4%, but its profit margin ranks second, reaching about 27%. Ternary copolymer thin films are limited by the shortage of the supply of the third copolymer, resulting in a low production scale, which also leads to a higher level of profit. It can be seen that the imbalance between supply and demand caused by technology has become a key factor affecting the profit of polypropylene production.

In order to achieve breakthroughs in the production of different kinds of polypropylene, on the one hand, it is affected by market consumption, and it is necessary to pay close attention to the opportunities of polypropylene production brought by consumption transformation; On the other hand lies in the technological breakthrough, especially the breakthrough of high-end brand production technology. It is believed that with the development of China's polypropylene industry in the future, China's polypropylene industry will inevitably upgrade both consumption and technology, so as to achieve a breakthrough in both consumption and technology in China's polypropylene industry.

Excerpt from - China Chemical Industry Information Weekly